In recent years, 3D printing technology has emerged as one of the most revolutionary innovations in the fields of manufacturing and design. What was once considered a futuristic concept is now transforming industries around the globe. 3D printing not only allows the creation of physical objects from digital models but also introduces new possibilities for production, design, and even product personalization.

This article will explore how 3D printing technology is revolutionizing key industries like healthcare, automotive, and construction, while significantly improving production and design efficiency.

What is 3D Printing?

3D printing is the process of creating three-dimensional objects by layering materials based on a digital design. Unlike traditional manufacturing methods, which often involve cutting or molding materials, 3D printing enables the creation of complex shapes that may be impossible to achieve using conventional methods.

Some of the most common 3D printing technologies include:

- Fused Deposition Modeling (FDM): Involves melting plastic filament and extruding it layer by layer to form the desired object.

- Stereolithography (SLA): Uses ultraviolet light to harden liquid resin, creating solid objects layer by layer.

- Selective Laser Sintering (SLS): Uses a laser to melt and fuse powdered material into the desired shape.

Impact of 3D Printing In Healthcare

In healthcare, 3D printing technology is having a transformative impact by enabling the production of more precise and personalized medical tools and devices. Here’s how it’s changing the healthcare sector:

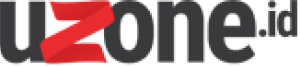

1. 3D Printed Organs and Medical Implants

One of the most groundbreaking advancements in 3D printing is the ability to create personalized medical implants and even 3D printed organs. For example, 3D printed bone implants can be customized to match a patient’s anatomy, reducing complications and speeding up recovery time.

2. Surgical Planning and Prototyping

3D printing allows doctors and researchers to print prototypes of organs or body parts for research and medical training. These printed models help medical professionals plan surgeries more accurately and understand the patient’s anatomy better before performing operations.

3. Prosthetics and Assistive Devices

3D printed prosthetics are becoming more affordable and customizable for patients. This personalization ensures a better fit and comfort. Moreover, these devices can be produced at a fraction of the cost of traditional prosthetics, making them more accessible, especially in developing countries.

How 3D Printing is Shaping the Automotive Industry

The automotive industry is also harnessing the power of 3D printing technology to enhance design, prototyping, and production efficiency. Here’s a closer look at its impact:

1. Prototyping and Component Production

One of the major applications of 3D printing in automotive manufacturing is in the creation of vehicle prototypes and automotive components. This technology allows automakers to quickly prototype parts and test various components before committing to mass production, reducing both time and cost.

2. Reduced Production Costs and Lead Time

By using 3D printing, automotive companies can reduce the amount of waste material used in production, leading to more efficient manufacturing processes. Additionally, 3D printing can speed up the production of spare parts, allowing car manufacturers to quickly respond to market needs.

3. Vehicle Customization

Some automotive companies are starting to offer vehicle customization through 3D printing, allowing customers to design and order bespoke vehicle parts and accessories, making each car more personalized and unique.

Innovations in Construction Through 3D Printing

3D printing technology is making significant strides in the construction industry, offering new ways to build more efficiently and sustainably. Here’s how 3D printing is changing the construction sector:

1. 3D Printed Homes

In several countries, 3D printing has been used to print homes and building components using materials like concrete or specialized composites. This technology allows for faster construction, cost savings, and more environmentally friendly practices.

2. More Efficient Construction Processes

With 3D printing, complex structural elements such as walls and bridges can be created with extreme precision, minimizing material waste and reducing labor costs. This makes 3D printing an ideal solution for building both functional and aesthetically appealing structures.

3. Customized Architectural Design

Because 3D printing allows for complex geometries and customized shapes, architects and builders can now explore innovative designs that were previously difficult or impossible to achieve with traditional construction methods.

Benefits and Challenges of 3D Printing Technology

Benefits:

- Faster Production: 3D printing accelerates the production timeline, allowing companies to quickly move from design to physical prototype.

- Cost Savings: With 3D printing, businesses can reduce production costs by minimizing material waste and optimizing the use of resources.

- Customization: This technology allows for personalized products and components, whether it’s a unique prosthetic or a custom part for a vehicle.

- Innovative Design: 3D printing unlocks new creative possibilities for designers, allowing for shapes and forms that traditional manufacturing techniques can’t achieve.

Challenges:

- Initial Investment Costs: The setup for 3D printing technology, including printers and materials, can require a significant initial investment.

- Scalability Issues: While 3D printing is excellent for small batch production or prototyping, it’s not yet ideal for large-scale manufacturing.

- Material Limitations: Currently, the range of materials that can be used in 3D printing is still somewhat limited compared to traditional manufacturing methods.

3D printing technology is reshaping industries like healthcare, automotive, and construction by making production processes more efficient, cost-effective, and customizable. From creating personalized medical implants to printing homes and vehicle parts, the potential applications of 3D printing are vast and continually expanding. While challenges such as high upfront costs and material limitations remain, the future of 3D printing looks promising as this innovative technology continues to evolve, offering new opportunities for growth, efficiency, and creativity.