Uzone.id – You probably know Zeiss for their amazing camera lenses, right? But did you know they make a whole lot more than that?

We visited their headquarters in Germany and saw all sorts of cool stuff they make. It’s not just cameras – they also have microscopes, binoculars, tools for making super-precise products, dental stuff, and even planetariums!

We got a tour from a cool guy named Kurt Becker, who used to work at Zeiss. He showed us around their museum, which is like a time capsule of all the amazing things Zeiss has invented over the years.

“I used to be a scientist here, working since 1986. I retired, but I believe in Zeiss, I was accepted here,” he said.

He invited and explained in detail the history of Zeiss, which was founded in 1846. He said that at the beginning of the company’s establishment, the first product created by Carl Zeiss was a microscope that he developed with physicist Ernst Abbe.

Starting from microscopes, Zeiss has now become a large company that does not only focus on developing camera lenses.

“Here are displayed Zeiss products and innovations. The company is not only known as a camera lens provider,” explained Becker.

After visiting the museum, Zeiss invited us to visit their R&D facility. What surprised us was that Zeiss did not keep their research and development process secret.

Many companies keep their ‘kitchen’ secret, either for fear of being copied by competitors or other considerations. But not Zeiss.

According to Zeiss Senior Director of Operations, Josef Kohnle, this was an exclusive experience for us to record what Zeiss does at this R&D facility.

“You are exclusively allowed to record here,” said Kohnle.

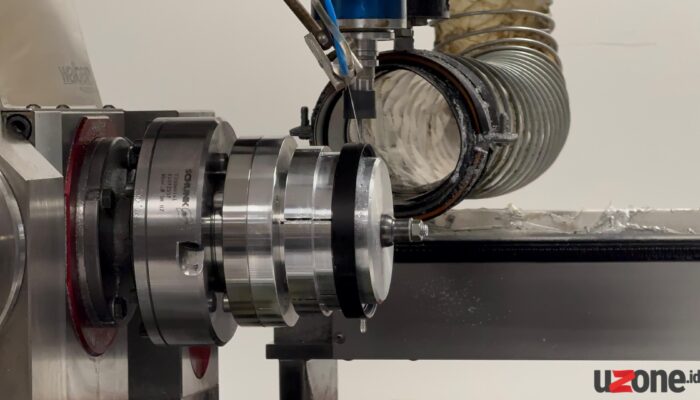

We were shown several stages of making lens bodies, which are still done by hand. Josef mentioned that the company does not prioritize shipping volume, but rather the quality of the products produced.

“That’s why some stages are still handmade, combined with machines for precision,” explained Josef.

One of the workers there showed how he painted the lens body for the focus point indicator. He applied bright yellow color slowly, and this was done without the help of a machine!

“This yellow color is to make it visible in the dark,” explained Josef.

Next, Josef showed how Zeiss makes super-precise lenses. This is to ensure that their lenses can be relied upon to capture various situations optimally.

“Zeiss camera lenses have won three Oscars in the Science and Engineering category,” he claimed.

Zeiss won these Oscars in 1987, 1999, and 2012. Besides showing off the prestigious trophies, Josef also (carefully) showcased one of Zeiss’s most expensive lenses, priced at EUR45,000 or more than USD50,000.

“Be careful holding it. You can feel the premium quality of our lenses,” concluded Josef.

There is only one R&D sector that Zeiss did not allow to be recorded, namely the Vivo Zeiss Imaging Lab. In this laboratory, Vivo and Zeiss collaborate to conduct various tests to meet the best and most consistent imaging standards.

Oliver Schindelbeck, Senior Smartphone Technology Manager for Zeiss Consumer Products, said that many tests are conducted to test a single camera module.

He said that each camera module undergoes at least 16,000 tests. These tests include light reflection, focus points, skin tone, backlight, bokeh effect, and so on. All of these are conducted with professionally designed equipment, ensuring the quality of smartphone cameras that can be used in various shooting scenarios.

“That’s just one camera module; there are even more tests if a phone has 2-3 camera modules,” he concluded.